Reliability Engineer: Skills, Responsibilities & Career Path

Discover insightful courses on this topic with Skilltrans. As we become increasingly reliant on technology, ensuring the reliability and efficiency of systems and processes is crucial. Precisely for this reason, the need for skilled Reliability Engineers grows. They keep our machines functioning, from complex medical equipment to everyday appliances. Working quietly behind the scenes, Reliability Engineers uphold the reliability and durability of our mechanical wonders, warranting they operate flawlessly and persistently. But who are these enigmatic figures in the engineering realm, and how does one embark on the journey to master their craft?

This comprehensive guide will embark on a journey into the captivating realm of Reliability Engineering, unraveling the mysteries of their critical role, the roadmap to becoming one, and the essential skills that empower them as masters of machines.

What is the Reliability Engineer?

A Reliability Engineer is a professional who focuses on ensuring that systems and components operate reliably and efficiently over their intended lifespan.

Engineers apply engineering principles and statistical methods to predict, prevent, and resolve issues related to system reliability. They analyze failure data, design reliability tests, develop maintenance strategies, and implement improvements. Their primary goal is to minimize the likelihood of failures and optimize maintenance practices, thereby enhancing the overall performance and safety of equipment, processes, and systems.

The Engineer is a behind-the-scenes hero in clinching the smooth operation of businesses and organizations. They work across various industries, including manufacturing, aerospace, energy, and technology.

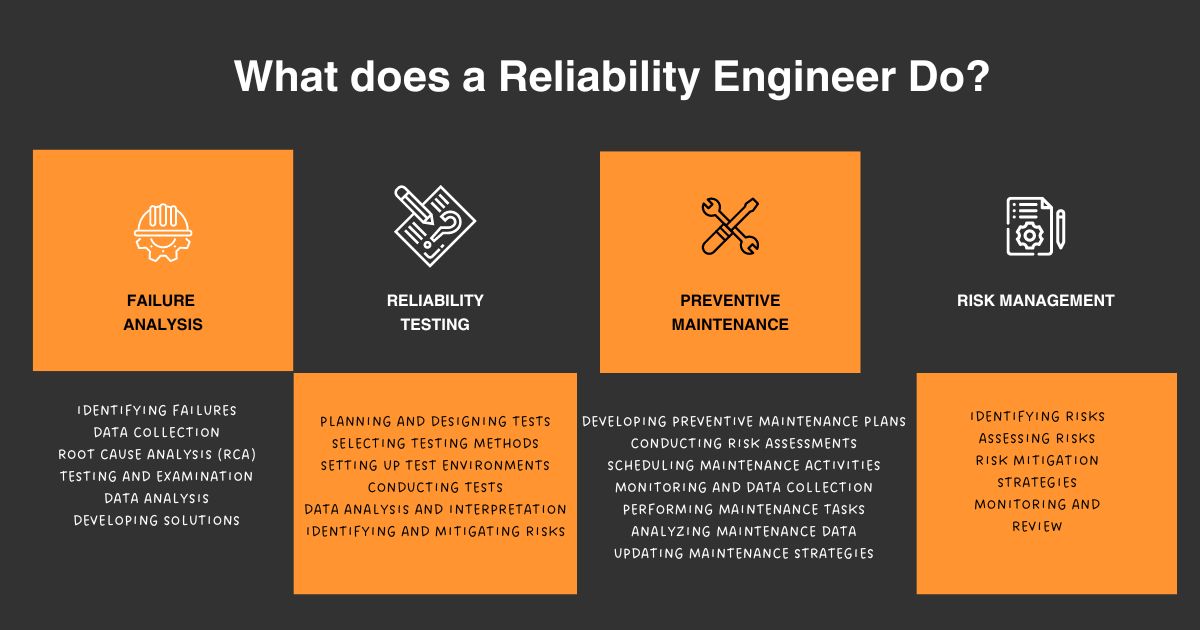

What does a Reliability Engineer Do?

Reliability Engineers are vital in preventing costly failures, enhancing safety, and ensuring the efficient operation of systems and equipment. Their work is essential in industries where system failures can have significant financial, safety, or environmental consequences.

Failure Analysis

Failure analysis is a core responsibility of an Engineer. When a machine or system malfunctions, a Reliability Engineer will investigate the root cause of the failure.

Identifying Failures

Reliability Engineers continuously monitor systems and equipment to detect failures. They use sensors, diagnostic tools, and data collection software to track performance metrics and identify anomalies. Additionally, they collect detailed reports of failure incidents from operators, technicians, and automated monitoring systems to gather comprehensive information about the failures.

Data Collection

Gathering historical data on similar failures, maintenance records, and operational logs provides context for the current failure. Engineers collect information on the failure mode, including the type of failure (e.g., mechanical, electrical), the conditions under which it occurred, and the symptoms observed.

Root Cause Analysis (RCA)

Reliability Engineers construct fault trees to systematically explore potential causes and employ fishbone diagrams (Ishikawa or cause-and-effect diagrams) to identify potential root causes across various categories, such as materials, methods, equipment, and environment. The 5 Whys technique, which has repeatedly asked "why" to drill down to the root cause, is also a common method used in RCA.

Testing and Examination

Conducting thorough inspections of failed components assists in identifying signs of wear, fatigue, corrosion, or other physical indicators of failure. In some cases, samples are sent to laboratories for detailed analysis, including metallurgical tests, chemical analysis, and microscopic examinations. This step is essential for understanding the physical and chemical factors contributing to the failure.

Data Analysis

Reliability Engineers apply statistical methods to analyze failure data, identify trends, and determine the probability of recurrence. They use reliability models to simulate different scenarios and predict the impact of various factors on system reliability.

Developing Solutions

Based on the findings from the analysis, Engineers recommend corrective actions to address the root causes of failure.

Reliability Testing

Reliability Engineers are integral to the process of reliability testing.

Planning and Designing Tests

Engineers start by planning and designing reliability tests tailored to the specific systems or components under evaluation. They choose appropriate testing methodologies based on the type of product and its expected operational environment.

Selecting Testing Methods

Several testing methods are employed to assess reliability, including accelerated life testing, highly accelerated life testing (HALT), and highly accelerated stress screening (HASS). Reliability Engineers select the most suitable methods to simulate long-term usage and identify potential failure modes. These methods uncover weaknesses and predict product lifespan.

Setting Up Test Environments

Reliability Engineers set up test environments that replicate the conditions under which the product will be used. Conditions are temperature, humidity, vibration, shock, and other environmental factors.

Conducting Tests

During the testing phase, Engineers monitor the performance of systems and components under the predefined conditions. They use various instruments and data acquisition systems to collect real-time data on how the product behaves under stress. This data includes information on failures, performance degradation, and other critical parameters.

Data Analysis and Interpretation

The data collected during reliability testing is analyzed to identify trends, patterns, and potential failure modes. Reliability Engineers use statistical tools and reliability analysis software to interpret the data and assess the reliability metrics, such as mean time between failures (MTBF) and failure rate. So they will understand the product’s performance and predict its reliability over time.

Identifying and Mitigating Risks

Based on the analysis, Engineers identify potential risks and failure modes that could affect the product’s reliability. They develop strategies to mitigate these risks, such as design modifications, material changes, or process improvements.

Preventive Maintenance

Preventive maintenance focuses on performing regular maintenance tasks to prevent unexpected failures and extend the lifespan of assets.

Developing Preventive Maintenance Plans

Reliability Engineers create detailed preventive maintenance plans tailored to specific equipment and systems. These plans outline the maintenance tasks, schedules, and procedures required to keep assets in optimal working condition.

Conducting Risk Assessments

Engineers analyze the impact of equipment failures on overall operations, safety, and costs. This risk-based approach can allocate maintenance resources effectively and target high-risk areas that could cause significant disruptions.

Scheduling Maintenance Activities

A key aspect of preventive maintenance is scheduling regular maintenance activities to minimize downtime and disruption. Engineers use maintenance management software to create and manage maintenance schedules. These schedules make sure that maintenance tasks are performed at optimal intervals based on equipment usage, age, and condition.

Monitoring and Data Collection

Reliability Engineers implement monitoring systems to collect data on key performance indicators (KPIs) such as temperature, vibration, pressure, and operational hours. This data shows early signs of wear and tear, allowing for timely maintenance interventions.

Performing Maintenance Tasks

Engineers oversee the execution of preventive maintenance tasks, making certain that maintenance personnel follow the established procedures and safety protocols. Maintenance personnel would lubrication, cleaning, calibration, inspection, and parts replacement.

Analyzing Maintenance Data

After completing maintenance activities, Reliability Engineers analyze the collected data to evaluate the effectiveness of the preventive maintenance program. They look for trends, patterns, and anomalies that could indicate underlying issues.

Updating Maintenance Strategies

Based on the insights gained from data analysis, Engineers continuously update and improve preventive maintenance strategies. They adjust maintenance schedules, procedures, and priorities to address emerging issues and optimize maintenance efforts.

Risk Management

Reliability engineers focus on the reliability and performance of systems, components, and processes that directly contribute to identifying, assessing, and mitigating risks.

Identifying Risks

Engineers should understand the systems and components and the various factors that could cause failures or suboptimal performance. Techniques like Failure Mode and Effects Analysis (FMEA) and Hazard and Operability Studies (HAZOP) are commonly used to identify potential failure modes and their effects.

Assessing Risks

Once risks are identified, reliability engineers assess their severity, likelihood, and potential impact. This assessment exposes prioritized risks based on their potential to disrupt operations. They use quantitative methods like statistical analysis and probabilistic risk assessment to measure and evaluate risks. Software tools such as ReliaSoft, RAM Commander, and Isograph are often employed to perform these analyses, providing detailed insights into risk levels and their potential impacts.

Risk Mitigation Strategies

After assessing the risks, reliability engineers develop and implement strategies to mitigate them. These strategies can include design changes, improved maintenance practices, redundancy, and the use of higher-quality components. Engineers may use tools like Fault Tree Analysis (FTA) and Event Tree Analysis (ETA) to explore different scenarios and determine the most effective mitigation measures.

Monitoring and Review

Risk management is an ongoing process. Engineers continuously monitor systems to detect any emerging risks or changes in existing risks. They use real-time data collection and monitoring systems, such as SCADA and IoT sensors, to gather information on system performance and identify potential issues before they escalate. Regular reviews and audits are conducted to evaluate the effectiveness of risk mitigation measures and make necessary adjustments.

How to Become a Reliability Engineer?

Becoming a Reliability Engineer requires a blend of formal education, relevant certifications, hands-on experience, and continuous skill development.

Education and Qualifications

To become an engineer, the minimum educational requirement is typically a bachelor's degree in engineering.

Earn a Bachelor's Degree

A bachelor's degree in a relevant engineering field is the typical starting point. Popular choices include Mechanical Engineering, Electrical Engineering, Industrial Engineering, or Manufacturing Engineering. These programs provide a strong foundation in engineering principles, mechanics, and problem-solving skills.

Consider a Master's Degree (Optional but Beneficial)

While not always required, a master’s degree in engineering or a related field can be advantageous. Advanced degrees often focus on specialized areas - reliability engineering, systems engineering, or quality assurance. Coursework in reliability engineering, statistics, quality control, failure analysis, and maintenance engineering is particularly beneficial, as understanding these areas is momentous for performing the duties of a engineer effectively.

Professional Certifications

The Certified Reliability Engineer (CRE) certification, offered by the American Society for Quality (ASQ), is highly regarded in the field. It validates a professional’s knowledge and skills in reliability engineering principles and practices.

Another valuable certification is the Certified Maintenance and Reliability Professional (CMRP), offered by the Society for Maintenance & Reliability Professionals (SMRP). This certification specifies maintenance and reliability best practices, emphasizing practical knowledge and application.

Gaining Relevant Experience

The next step to becoming a reliability engineer is actively seeking opportunities to apply theoretical knowledge in real-world settings and staying informed about industry advancements.

Internships and Co-Op Programs

Internships and co-op programs often offer exposure to various aspects of engineering projects, including design, testing, and maintenance. Working alongside experienced professionals, interns can learn about industry standards, best practices, and the latest technologies used in engineering. This early exposure aids build foundational skills and understanding of the field, making it easier to transition into full-time roles after graduation.

Entry-Level Positions

Starting in entry-level positions related to reliability, such as quality assurance, maintenance engineering, or production engineering, provides essential experience for aspiring reliability engineers. In these roles, individuals can gain practical insights into the operations and maintenance of systems or equipment. They learn to identify potential reliability issues, conduct root cause analysis, and implement corrective actions.

Project Management Experience

Gaining experience in project management is beneficial for reliability engineers, as it includes planning, executing, and evaluating projects to improve system reliability. In project management roles, engineers familiarize themself with managing resources and set timelines.

Continuous Learning and Adaptation

Aspiring engineers should take advantage of workshops, seminars, and training programs to stay updated with the latest trends, techniques, and tools. Online courses and certifications in reliability engineering and related fields provide opportunities for continuous education and skill development.

Networking and Professional Associations

Joining professional associations like the American Society for Quality (ASQ), the Society for Maintenance & Reliability Professionals (SMRP), and the Institute of Electrical and Electronics Engineers (IEEE) submits access to resources, networking opportunities, and continuing education.

Essential Skills for a Reliability Engineer

Reliability engineers are vital in optimizing equipment performance, maximizing uptime, and minimizing organizational maintenance costs. Here's a breakdown of the essential skills for a Reliability Engineer, combining technical expertise, analytical thinking, and strong communication abilities:

Technical Skills

A strong foundation in engineering principles is decisive for an Engineer. You need to build a deep understanding of mechanical, electrical, and industrial engineering concepts. Proficiency in using reliability engineering software tools, such as Weibull++ and ReliaSoft, is fundamental.

Additionally, expertise in statistical methods and tools for data analysis, such as Minitab, MATLAB, or Python, allows for accurate data interpretation and reliability assessments. Familiarity with Failure Modes and Effects Analysis (FMEA) and Root Cause Analysis (RCA) identify potential failure modes and implement corrective actions. Knowledge of Reliability-Centered Maintenance (RCM) principles is also necessary to optimize maintenance practices based on reliability principles.

Analytical Skills

The ability to collect, analyze, and interpret data is a cornerstone for identifying trends, patterns, and anomalies that could impact system reliability. Furthermore, expertise in risk assessment enables Reliability Engineers to manage and mitigate risks associated with equipment and system operations effectively.

Communication Skills

Effective verbal communication skills facilitate collaboration with cross-functional teams and the presentation of findings. Interpersonal skills are also important for building relationships and fostering teamwork within an organization.

Industry Knowledge

Knowledge of sector-specific requirements ensures compliance with regulatory standards and enhances the overall reliability of systems and processes. Staying informed about industry developments and standards allows Reliability Engineers to apply the most current and effective engineering practices.

Discover insightful courses on this topic with Skilltrans. Please click on the course name below to learn more:

Career Development (2 of 2): Land That Job, Plain & Simple

In this course, you will learn:

How to prepare for the job interview

How to deal with the questions that might come up in the interview

How to negotiate your starting salary (yes you can negotiate)

And finally some closing advice on holding on to that dream job.

This course includes:

Video lectures

Quiz to test your retention

Significant number of resources to do a deeper dive into his topic.

Upwork Mastery: Step by Step Guide to Grow Freelance Earning

This course has been meticulously crafted by freelancer, for freelancers.

Are you ready to kickstart your freelance career and boost your earnings?

In 2022 alone, clients on Upwork paid out over $3.3 billion to freelancers. It's time to grab your slice of that lucrative pie!

Throughout this course, you'll embark on a practical journey, equipped with lessons, workbooks, and real-world applications. Plus, when you enroll, you gain exclusive access to group mastermind sessions and the thriving Upwork University Community Space.

HOW TO ALIGN YOUR CAREER WITH YOUR PURPOSE

This course is designed to help individuals discover and align their careers with their life purpose.

Through a series of modules, participants will explore their core values, passions, strengths, and the impact they want to make in the world.

By the end of the course, participants will have a clear understanding of their purpose and practical steps to align their career path with it.

Conclusion

The world of Reliability Engineering offers a compelling blend of technical challenge, The world of Reliability Engineering offers a compelling blend of technical challenges, strategic decision-making, and the satisfaction of keeping the wheels of the industry turning. Reliability Engineers play a critical role in ensuring that systems and processes operate smoothly, efficiently, and with minimal downtime.

Remember, the journey to becoming a successful Engineer is a continuous process of refinement. Embrace the challenges, hone your skills, and forge your path as a guardian of machine reliability. The future of efficient operations and a smoothly functioning world rests on the shoulders of these meticulous masters.

If you have a dream of becoming a Reliability Engineer, you can take Skilltrans courses. We have useful courses at the most affordable prices.

Meet Hoang Duyen, an experienced SEO Specialist with a proven track record in driving organic growth and boosting online visibility. She has honed her skills in keyword research, on-page optimization, and technical SEO. Her expertise lies in crafting data-driven strategies that not only improve search engine rankings but also deliver tangible results for businesses.